American researchers have devised a new way to combat plastic and food waste simultaneously. They created a replacement for plastic packaging films using banana peels. The new material is equal in quality to conventional plastic but decomposes in the soil hundreds of times faster.

Bananas are one of the world’s most popular and widely consumed edible fruits. They rank fourth in total production, behind only rice, wheat, and corn. Moreover, bananas are consumed in their natural form, such as chips, flour, juices, jam, baby food, and other products.

About a third to half of a banana’s mass comprises the peel, which is discarded without any processing. Subsequently, due to anaerobic digestion, an unpleasant odor is formed in landfills and various compounds that pollute the atmosphere and soil. However, the tens of millions of tons of banana peels produced yearly could be used to produce biodegradable plastic substitutes, for example.

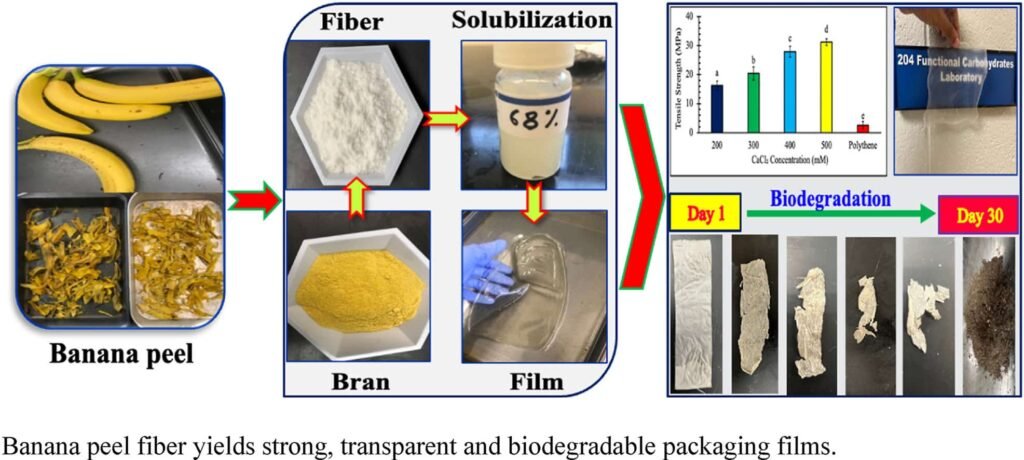

Researchers from the University of South Dakota (USA) proposed recycling banana peels, extracting lignocellulosic fiber from them, and creating biodegradable packaging films. Thus, replacing up to 40 percent of all plastic produced worldwide is possible. The scientists described the results of their work in an article published in the journal Sustainable Chemistry and Pharmacy.

Standard plastic packaging, such as plastic bags, decomposes in the soil for hundreds of years. Despite many projects to recycle plastic waste, most of it ends up in landfills, soil, oceans, and inside living organisms in the form of micro- and nanoplastics. This leads to serious consequences for the environment and human health.

The authors of a new study have found a promising and inexpensive alternative. First, the scientists crushed the used peels using a blender and chemically treated the raw material to extract the lignocellulose. The extracted fibers were then subjected to bleaching, distillation, and further chemical treatment, after which the material was formed into films and dried.

The research team previously performed a similar procedure with avocado peels, coffee grounds, and millet. Now they have created a material that, in its characteristics (strength, transparency, water permeability, elasticity), is similar to its plastic counterpart but decomposes much faster. When buried in soil within a month, the banana peel films degraded more than 90 percent without producing harmful or dangerous byproducts.

Further research by the team of scientists will be aimed at improving the films’ characteristics and studying the developed process’s scalability and commercialization.