German and American scientists have proposed a method to quickly reduce the heating of electronic equipment and speed up battery charging several times. The researchers achieved such impressive results with the help of a single innovation.

All digital electronics generate heat due to the operation of transistors, which act as switches, stopping electrical current or allowing it to flow. In other words, heat is a by-product of energy production. The device may overheat and fail if you do not get rid of the “excess” heat. Therefore, electronic components require cooling systems often represented by radiators. They are usually made from copper and aluminum plates with high thermal conductivity.

However, these metals have a big problem. They are good conductors of electricity. An electrically insulating oxide or nitride layer is made between the metal and the component to reduce their electrical conductivity. But there is also a drawback here – poor heat conductivity.

Scientists have long been trying to find a material to replace the intermediate layer with good thermal conductivity. This was accomplished by a group of physicists led by Matthias Mühle from the most significant European association of applied research institutes, the Fraunhofer Society, and their colleagues from the USA. Diamond became a lifesaver.

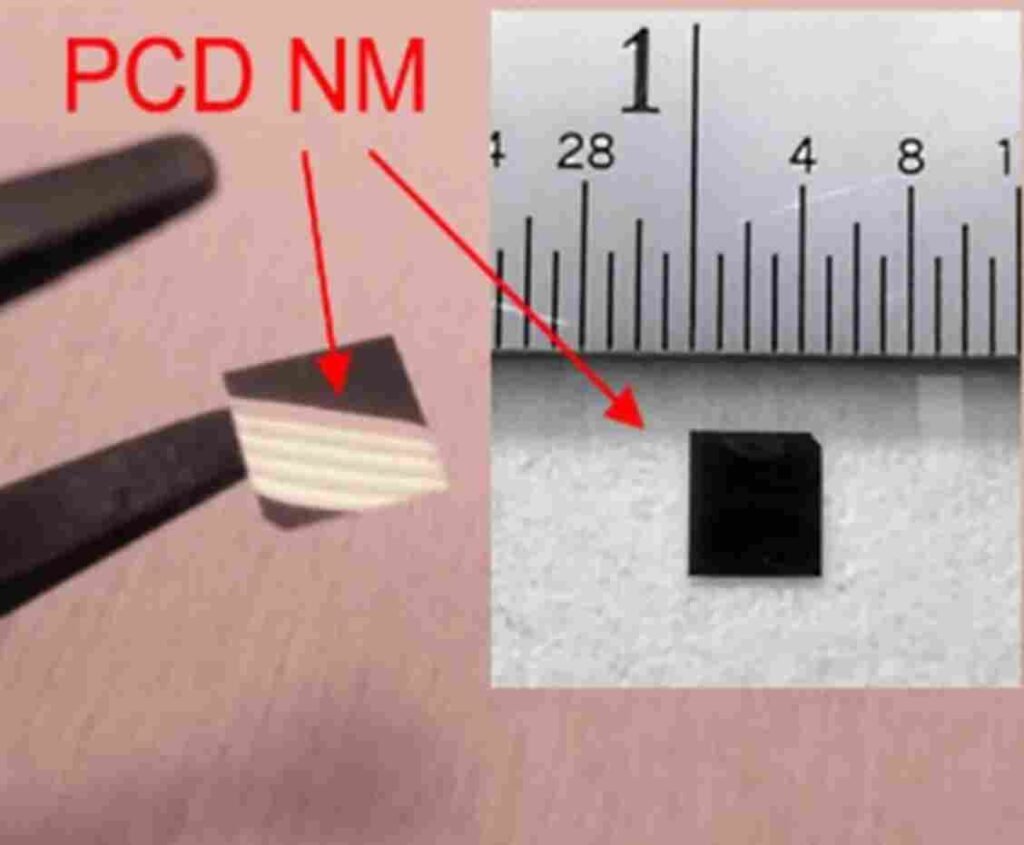

Diamond heat sinks are just beginning to be applied to electronics products. Their main advantage is dissipating much greater specific thermal power than conventional heat-removing materials. However, diamond heat sinks are more than two millimeters thick, making them difficult to install on small electronic components.

Mühle and his team have developed flexible nanomembranes made from synthetic diamonds that are thinner than human hair (less than a micrometer thick). According to the developers, their material can be built into almost any electronic component and can gently heat elements to 80 degrees Celsius.

Physicists noted that their flexible electrically insulating nanomembranes can reduce the thermal load of electronic components by ten times, which, of course, will increase the energy efficiency and service life of the components themselves and the entire device in which they are contained. Another advantage of such nanomembranes is that when used in charging stations, for example, electric vehicles can increase the charging speed by five times.

“For now, our main goal is electric vehicles. Calculations show that these nanomembranes can be used to cool energy electronics associated with converting electrical energy,” explained Mühle.

Scientists have already applied for a patent and will soon begin applied research: they will test diamond nanomembranes in electric vehicles and telecommunications systems. If the tests are successful, the developers plan to launch industrial production of their cooling products.